1847

Nils Ericson, a well-known canal and railway builder in Sweden, takes over Rånnum Manor.

History

We have a long, eventful history behind us. The company has undergone many changes to become the stable, international smelter it is today.

From having been a country manor and then a paper mill, it became an alloying plant with an annual capacity of 20,000 metric tons per year. Since then, Vargön Alloys AB’s journey has led us to shipping a million metric tons every year in our transport system.

The story begins with Nils Ericson.

Nils Ericson, a well-known canal and railway builder in Sweden, takes over Rånnum Manor.

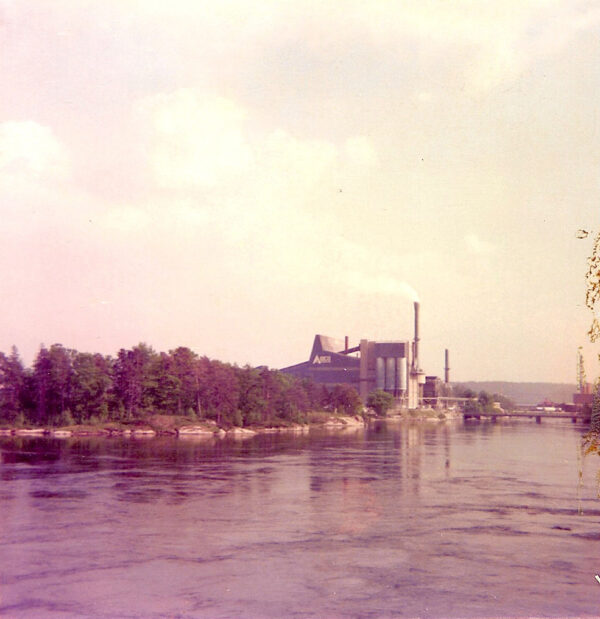

He sells the land and Wargöns AB, a paper and wood pulp mill, is founded. The company chooses land right alongside the Göta River, mainly for the hydropower used for the industrial process, but also for shipping forestry products.

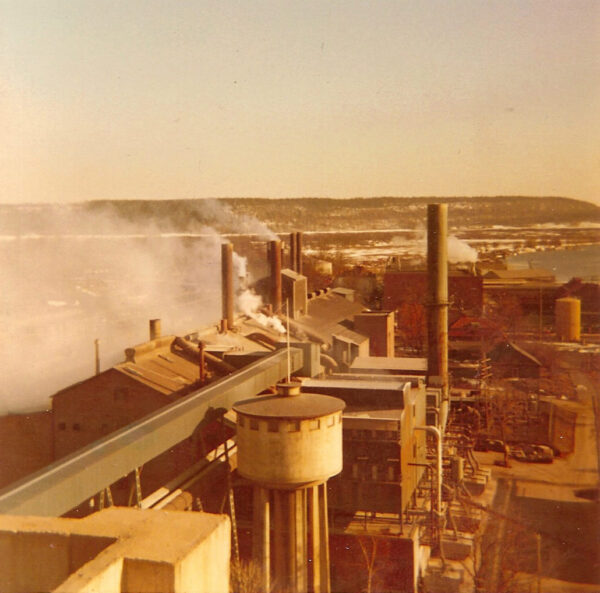

The business grows to include a sulfite pulp mill and a paper mill. Wargöns AB is now one of northern Europe’s biggest forestry companies.

At this time, the hydropower rights in Göta River are sold to the Swedish state and Wargöns AB undertakes to receive a large quantity of electricity for 40 years. It must consume 3,700 hp, or 2.8 MW in modern units. Because it’s not possible for the paper and pulp mill to consume such an enormous quantity, the company decides to build an electric smelter to produce silicomanganese.

The company installs the first alloy furnace, thereby sharply increasing the demand for electricity. That same year, the company purchases furnaces, transformers and instrumentation for silicomanganese and ferrosilicon.

The alloy works is expanded and modernized. Wargöns AB now has an annual capacity of approximately 20,000 metric tons. The company acquires many other properties over time and develops into a business with major forests, ironworks, mines, cellulose and wood pulp mills, sawmills and power stations.

The government takes over the business. The company is restructured.

Experiments begin with energy recovery and flue gas cleaning.

The first energy recovery system is commissioned. The great interest in energy recovery is largely due to the need for heat to dry pulp, and to boil wood chips. The smelters produce a great amount of surplus heat which can now be used very efficiently.

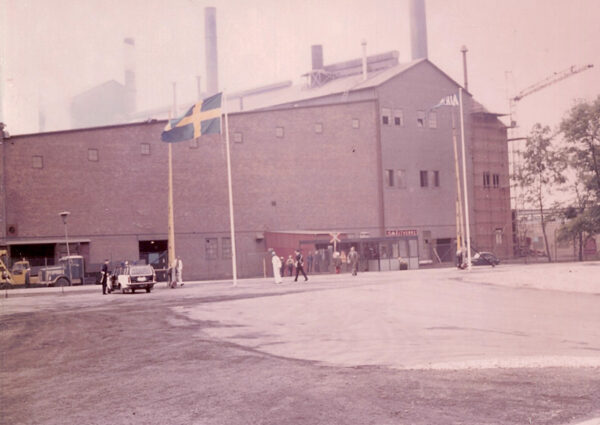

The American company Airco acquires Wargöns AB’s shares, but it is only interested in the smelter. The paper mill is sold on to several other mills and electricity distribution to Skandinaviska Elverk. Later, the forests and land are also sold.

What remains of the company is formed into Airco Alloys AB. The company now focuses on the production of ferrochrome and ferrosilicon. The company builds Furnace 12, the world’s biggest smelting furnace thus far.

British Oxygen Corp. acquires Airco Alloys AB. The company and the divested alloy division are sold to Fides AG and change their name to Vargön Alloys AB.

Vargön Alloys AB is now a subcontract producer that only converts raw materials to ferrochrome.

The operation begins supplying hot water to the Vänersborgs district heating network. This enables the recovery of additional heat from the flue gases while also gaining customers for the heat produced.

Together with the Mellansvenska Löntagarfonden wage earners’ investment fund, four members of the management team acquire all of the shares in Vargön Alloys AB.

Vargön Alloys AB was one of the first alloy works to receive ISO 9002 certification by Lloyds for its quality management system.

The investment fund sells its shareholding and Vargön Alloys AB successfully runs the company for 21 years despite the lack of a major backer.

The Yildirim Group of Companies acquires Vargön Alloys AB to supplement its own production of ferrochrome and chrome ore. This not only provides the company with a stable supply of high-quality chrome ore, but also a stronger financial position.

The business strategy changes. Moving forward, Vargön Alloys AB seeks niche markets to compete with simpler grades.

Vargön Alloys AB celebrates its centennial as a smelter by presenting its niche products to customers and suppliers. The products developed prove to be a great choice as demand increases and more furnaces begin production.

Vattenfall completes a hot water main between Trollhättan and Vargön, allowing Trollhättan Energi to use surplus heat from Vargön Alloys AB – an important environmental protection measure.

As of this year, Vargön Alloys AB are a part of CoreX Holding, based in the Netherlands.

Vargön Alloys AB enjoys a very strong market position, as Sweden’s only smelter, and one of the biggest in the world. The company’s transport system handles around 1 million metric tons per year.